By Jeevith Senaratne

An industry’s response to an unprecedented crisis such as the COVID-19 pandemic and its aftermath is a testament to its ability to weather the storm and come out stronger on the other side. This was particularly true for Sri Lanka’s apparel sector.

While the initial wave of COVID-19 posed many challenges to the industry, it now appears that the Sri Lankan apparel sector’s response to the crisis has enhanced its long-term competitiveness and could reshape the future of the global fashion industry and how it operates.

Hence, analysing the industry’s response has significant value to the stakeholders across the industry, especially since some of these outcomes were perhaps not foreseen amidst the turmoil at the onset of the pandemic. Further, the insights explored in this article are also likely to have broader business applicability, particularly from a crisis adaptation perspective.

Reflecting on the Sri Lankan apparel’s response to the crisis, two factors stand out; the industry’s resilience stemming from its capacity to adapt and innovate and the basis of the relationship between apparel manufacturers and their buyers.

Rapid adaptation

The initial challenge stemmed from the volatility caused by COVID-19 in buyer markets. Future export orders –typically in development up to six months in advance – were essentially cancelled, leaving companies with virtually no pipeline. Faced with a sharp downturn in the fashion industry, manufacturers adapted by switching to Personal Protective Equipment (PPE) production, a product category that saw an explosion of global demand given the rapid spread of COVID-19.

This proved challenging due to a multitude of reasons. Initially, prioritisation of worker safety via stringent adherence to health and safety protocols required, among many other measures, production floors to be altered as per social distancing guidelines causing existing facilities challenges in playing host to the number of employees it had previously. Additionally, employees across the board needed upskilling, given that many companies had little or no experience in PPE production.

However, overcoming these issues, PPE production commenced, providing revenue for manufacturers to persist through the initial pandemic period. Most importantly, it enabled companies to retain their employees and survive through the initial period. After that, manufacturers began to innovate – for instance, developing fabrics with improved filtration, ensuring greater effectiveness at keeping the virus at bay. Hence, from having little to no experience in PPE, Sri Lankan apparel companies transitioned within months to producing their improved versions of PPE items, which met the stringent compliance standards of export markets.

Technology-driven innovation

In the fashion industry, the pre-pandemic development cycle tended to rely on traditional design processes; that is, buyers preferred to touch and feel garments/fabric samples in multiple iterative rounds of development samples before confirming the final production order. However, this was no longer possible with the closure of both buyer offices and offices of apparel companies in Sri Lanka. Sri Lankan manufacturers adapted to this challenge by leveraging 3D and digital product development technologies, which had existed pre-pandemic but had low rates of utilisation.

Leveraging 3D product development technology to its full potential brought in a host of improvements – including reducing the duration of the product development cycle by a whopping 84% – from 45 to just 7 days. The adoption of this technology also facilitated advances in product development, as it became easier to experiment with greater colour and design variations. Going even further, apparel companies such as Star Garments (which the writer is employed at) and other larger players in the sector commenced virtual photoshoots using 3D avatars since, with the pandemic-induced lockdowns, it was challenging to organise photoshoots with actual models.

The images generated through the process enabled our buyers/brands to continue their digital marketing efforts. Importantly, this further reinforced Sri Lanka’s reputation as a trusted end to end apparel solutions provider and not just a manufacturer. Sri Lankan apparel companies being ahead of the curve in technology adoption before the onset of the pandemic also helped significantly since they were already familiar with digital and 3D product development.

Long-term relevance

These developments will continue to be relevant in the long term, with all stakeholders now having recognised the value of these technologies. Compared with 15% before the pandemic, Star Garments currently employs 3D technology for more than half of its product development.

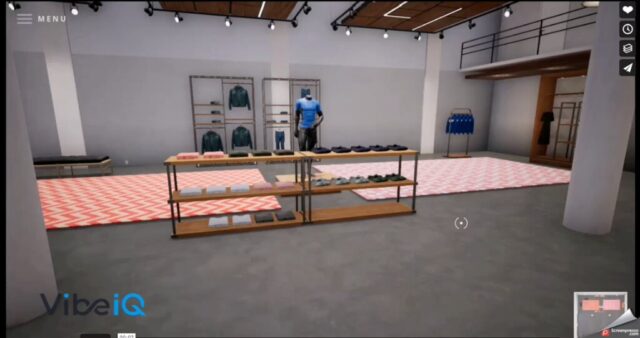

Using the impetus in terms of adoption provided by the pandemic, Sri Lanka’s apparel sector leaders, such as Star Garments, are now experimenting with value-added propositions, such as virtual showrooms. This will enable end consumers to view fashion items in 3D-rendered virtual showrooms which resemble buyers actual showrooms. While the concept is under development, once adopted, it can potentially transform the e-commerce experience for buyers of fashion items and hence have far-reaching global implications. It would also enable apparel companies to showcase their product development capabilities far more effectively.

Strategic partnerships

The cases laid out above demonstrate how the Sri Lankan apparel’s adaptability and innovation led to resilience, improved competitiveness, and enhanced the sector’s reputation and trust among buyers. However, this response is strongly leveraged and may not have been possible if not for the strategic partnerships Sri Lanka’s apparel sector has cultivated over decades with its buyers. The impact of the pandemic on the industry could have been significantly worse if the relationships with buyers were transactional and the country’s offering was commodity-driven.

With Sri Lankan apparel companies being seen as trusted long-term partners by buyers, in many cases, there were compromises at both ends in dealing with the pandemic’s impact. It also presented greater opportunities to collaborate in arriving at solutions. The foregoing of traditional product development and leaping into 3D product development is an example in this regard.

In conclusion, the Sri Lankan apparel’s response to the pandemic will likely provide us with a competitive advantage. However, the sector must refrain from ‘resting on its laurels’ and continue to stay ahead of our competition in technology adoption and innovation. Practices and initiatives which yielded positive results during the pandemic should be institutionalised. Collectively, these can play a critical role in achieving the vision of transforming Sri Lanka into a global apparel hub in the near future.

(Jeevith Senaratne currently serves as the Treasurer of the Sri Lanka Apparel Exporters Association. An industry veteran, he is a Director of Star Fashion Clothing, an affiliate of the Star Garments Group, of which he is a Senior Manager. An Alumni of the University of Notre Dame, he holds a BBA and MSc in Accountancy.)